Project Overview

CLIENT

Multi-national logistics provider

PROJECT

Technology update and retrofit. Improved employee efficiencies.

SIZE

Approximately 23,162 drop-boxes, nationwide

TIMEFRAME

18 months

“Many thanks to each of you for your contributions and tireless efforts to make this electronic control box upgrade an adventure like no other! No, we didn’t imagine the project lasting as long as it did; however, this new and different initiative brought challenges unforeseen! Thanks for joining us on this journey!”

T.A.

The Problem

Our client had been quick to recognize an increase in the retail industry’s omni-channel selling strategies. The client’s customers (in this case, mostly individuals or small businesses) needed real-time tracking for packages placed in drop-boxes.

The inherent inefficiency of the existing system was that the process was manual; it required the drivers (employees) to visit the drop box each day to pick up packages. The drivers had to manually change the status of the control box indicator to show if they had picked up packages from that particular drop box. This communicated to the consumer whether their package would be picked up on the day they placed it in the drop box or the following day. After the new technology was installed, the new drop box unit allowed the Driver to flip the status of the control box via their smart devices.

Under normal circumstances, our client would have assigned their own technicians to the project. But the sheer scale of the undertaking led them to partner with Bailiwick® as a provider of technical expertise, deployment services, and inventory management.

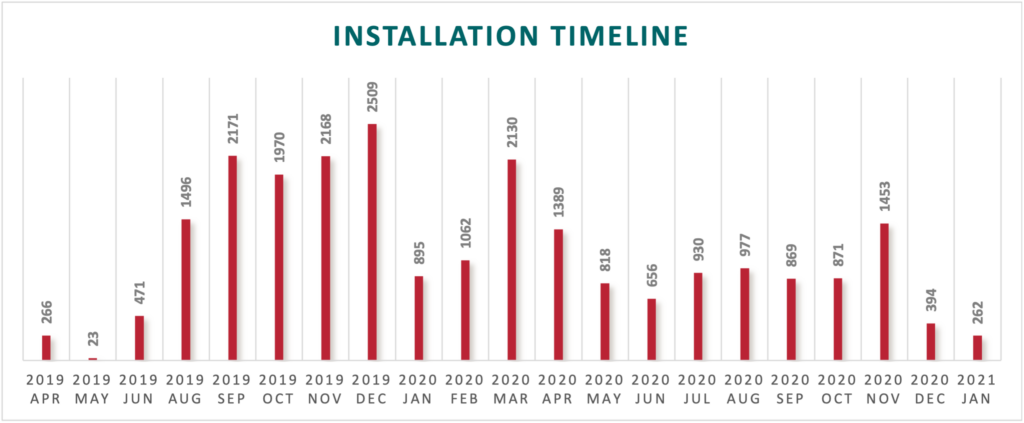

The project started pre-COVID-19, but once the full impact of the pandemic became apparent (despite a genuine desire to accelerate the pace) a delay of roughly six months was the eventual outcome.

The Solution

The client had 35,000 drop-boxes across the U.S., 23,162 of which required retro-fitting with a new control pad. With an initial goal of one hour to do each of those 23,162 conversions, we had hoped to complete the project in 18 months. However, a variety of unforeseen circumstances (supply chain, extensive delays out of China, and civil unrest) slowed down the roll-out by six months.

The original timeline was based on Bailiwick’s strategy to deploy dedicated technicians on dedicated routes. It was our belief that this dedication was essential to the success of the project. It minimized the number of people who physically came into contact with a box… it increased the chances of a successful retro-fit and installation… it generated consistency across the entire endeavor… and it resulted in a high degree of supportability from a troubleshooting standpoint.

On such a complex, long-term and fluid project, constant and open communication was essential. Weekly (at a minimum) meetings and a shared project management platform ensured that everyone was operating with the same information as we worked to achieve common goals.

As part of the service, Bailiwick created a detailed and extensive data report for the client. The report (which also included timeline and inventory management) allowed them to make informed, efficient and financially prudent decisions.

23,162

Boxes (sites) visited

19,900

Control Boxes upgraded

5 pieces

of equipment per box

Materials Management was responsible for roughly 100,000 pieces of equipment.

The Outcome

Despite the unforeseen delays, the project was a success. So much so that the client presented Bailiwick with a service award for our partnership and our role in the successful completion of the job.

We mentioned earlier that from the Bailiwick perspective, this project was truly history making. The scope of the effort is reflected in a few of the basic inventory management numbers.

By any metric, this was a massive project. It was a project that required trust, collaboration, creativity and attention to detail.

Ultimately, we delivered on our promise to use innovative thinking to provide an individualized solution that exceeded our client’s expectations.